What are the simulation analysis methods for injection molded magnets?

https://www.nbvsmagnetic.com/blog/magnet-industry-news/Injection molded magnets are widely used in modern electronic and mechanical equipment, and their performance and quality directly affect the efficiency and stability of the equipment. Therefore, the simulation analysis of injection molded magnets is of great significance. This article mainly introduces the simulation analysis method of injection molded magnets.

1、Theoretical basis

Injection molded magnets are mainly composed of iron, boron, nickel and other elements, which are mixed through specific proportions and processes to form a uniform composite material. During the injection molding process, this composite material is injected into the mold through high temperature and high pressure, and after cooling and shaping, the magnet we need is formed.

2、Simulation analysis software

When conducting simulation analysis of injection molded magnets, we need to use some professional simulation analysis software. Such as ANSYS, ABAQUS, COMSOL, etc. These softwares provide a wealth of physics modules that can simulate various situations of magnets during the injection molding process.

3、Simulation analysis steps

3.1 Build the model

First, we need to establish a three-dimensional model of the magnet in the simulation analysis software. This model should include all parts of the magnet, such as core, housing, pole pieces, etc. At the same time, we also need to set appropriate boundary conditions and initial conditions in the model.

3.2 Define material properties

After the model is established, we need to define some basic properties for the magnet material, such as density, elastic modulus, Poisson's ratio, thermal expansion coefficient, etc. These properties have an important impact on subsequent calculation results.

3.3 Set simulation parameters

Next, we need to set some simulation parameters, such as injection temperature, pressure, time, injection speed, etc. These parameters will affect the microstructure and macroscopic properties of the magnet.

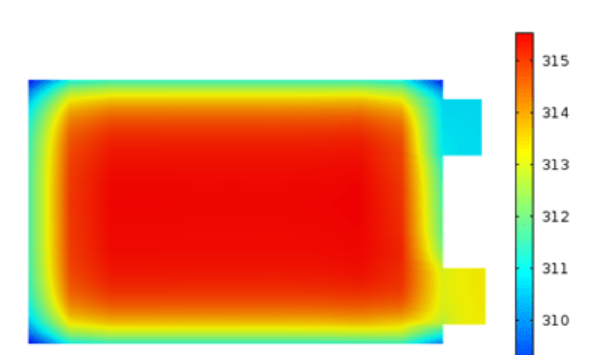

3.4 Perform simulation calculations

After setting all parameters, we can perform simulation calculations. During the calculation process, the software will simulate various situations of the magnet during the injection molding process, such as melting, flow, cooling, phase change, etc. Through these simulations, we can obtain the microstructure and macroscopic properties of the magnet.

4、Result analysis

Based on the results of simulation calculations, we can conduct a comprehensive analysis of the performance of the magnet. Such as the saturation, magnetic force, coercivity of the magnetic core, etc.; the hardness, strength, wear resistance, etc. of the shell; the current density, resistivity, etc. of the pole piece. These results can help us optimize the injection molding process and improve the performance and quality of the magnets.

5、in conclusion

The simulation analysis of injection molded magnets is a complex task that requires professional simulation analysis software and rich physical knowledge. Through simulation analysis, we can fully understand the various situations of the magnet during the injection molding process, providing an important reference for optimizing the injection molding process and improving the performance and quality of the magnet. Hope this article can be helpful to readers.

Magnet category

"Since 2006, we found Mr.Guo and get products from him. We used magnets under the earth for the gas and water pipe industries. We have met no problem. We have been working in very happy ways. We have many cooperation. Every year, we spent time together and sometimes, we invited him to Korea. He is our younger brother. Strongly recommended!!"

"Since 2006, we found Mr.Guo and get products from him. We used magnets under the earth for the gas and water pipe industries. We have met no problem. We have been working in very happy ways. We have many cooperation. Every year, we spent time together and sometimes, we invited him to Korea. He is our younger brother. Strongly recommended!!"

--------Mr. Tae Lee Korea

"I had email to Mr. Guo for rare earth magnet requirements. They replied my e-mail promptly, and were very professional. Mr. Guo’s team still continues to deliver rare earth magnets to our agreed specifications with a very high quality standard since 2012. His team is very professional and thorough with its work. Based on my experience, I would highly recommend them."

"I had email to Mr. Guo for rare earth magnet requirements. They replied my e-mail promptly, and were very professional. Mr. Guo’s team still continues to deliver rare earth magnets to our agreed specifications with a very high quality standard since 2012. His team is very professional and thorough with its work. Based on my experience, I would highly recommend them."

------Mr.Tauphik India